Floor Surface Roughness Testing

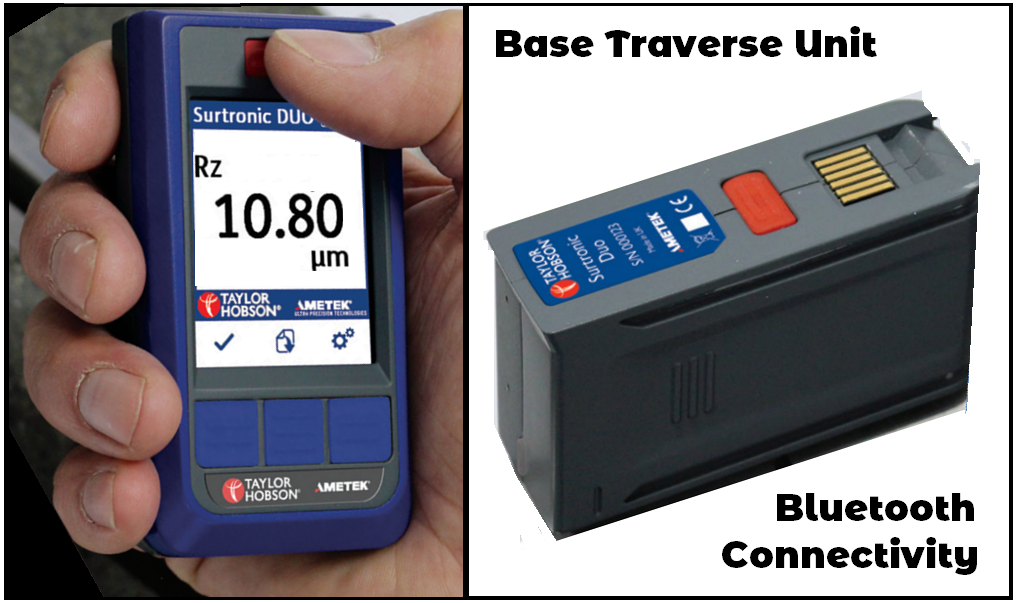

Floor Surface Roughness Testing consists of measuring, at microscopic level, how rough or smooth a floor surface is. It is accomplished using a lightweight handheld portable test equipment known as the 'Surtronic Duo', which measures the Rz value of the floor surface (As well as other parameters not used in Floor Testing - See bottom of page). The equipment consists of the handheld controller attached via blue tooth connectivity to a base unit which sits on the floor.

The Surtronic Duo-2 Surface Roughness Tester (below)

The Latest Surtronic Duo-2 Surface Roughness Tester (below)

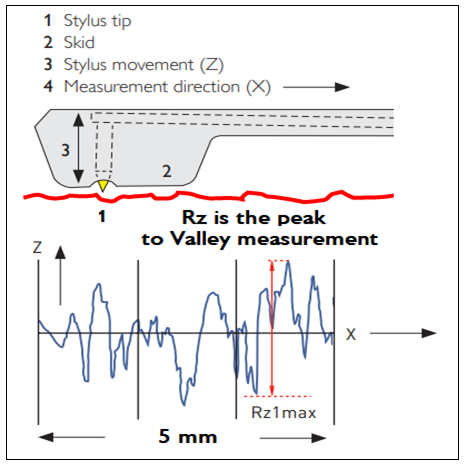

How Floor Test Values Are Measured

The floor testing equipment takes microscopic readings in ‘microns’ or ‘micrometre’ (µm) by dragging a needle like diamond stylus (pointer) set in the base unit across the ground surface for 5mm (0.2 inch). A piezo-electric pick-up detects the very tiny undulations of the surface to provide the Rz Value (Average peak to valley height).

Surface Roughness Test Equipment Stylus motors across the surface

Floor Surface Roughness seen under a microscope

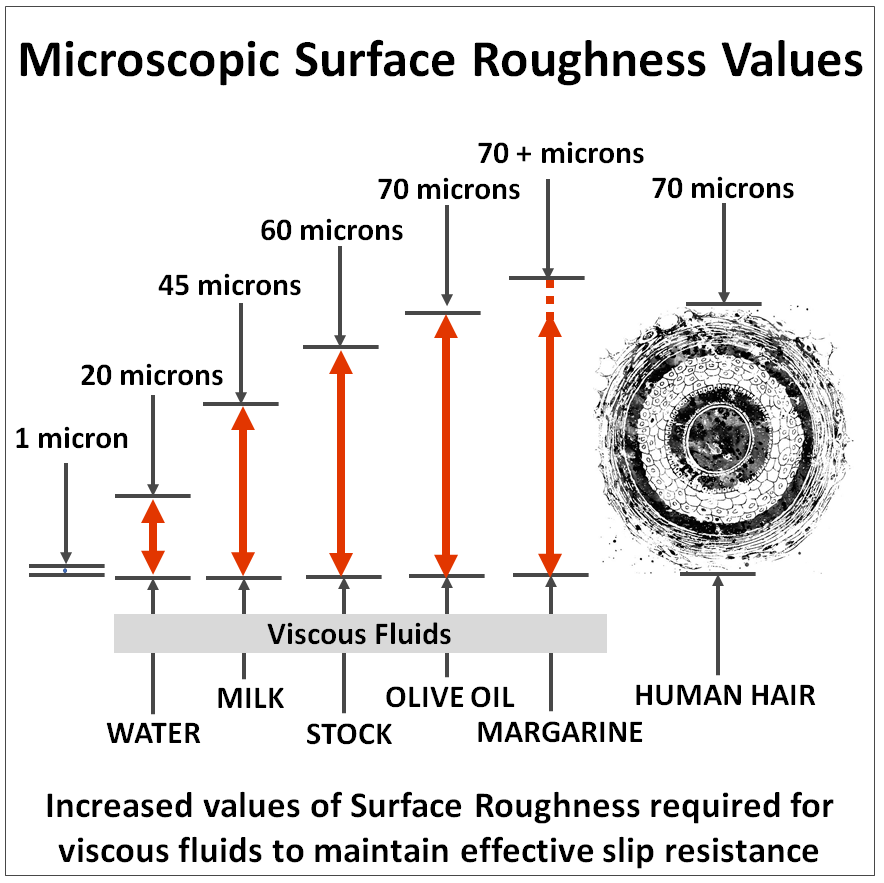

Surface Roughness Rz Values - What They Mean

The value 'Rz' is measured in ‘microns’ or ‘micrometre’, symbol ‘µm’, which is one-thousandths of a millimetre (0.001 mm / /1×10⁻⁶ metre / 0.000039 inch). A human hair is 70 Microns thick and a floor surface suitable to provide a reasonable degree of surface roughness when contaminated with water should be as a minimum, 20 microns. But when contaminated with more viscous (thicker) liquid contaminants requires higher values; e.g., Milk is 45 µm+, Stock is 60 µm +, Olive oil 70 µm +, Margarine > 70 µm +

Video of Surface Roughness Test

See a video of the surface roughness test as supplied by Taylor Hobson (UK)

Taking Surface Roughness Readings

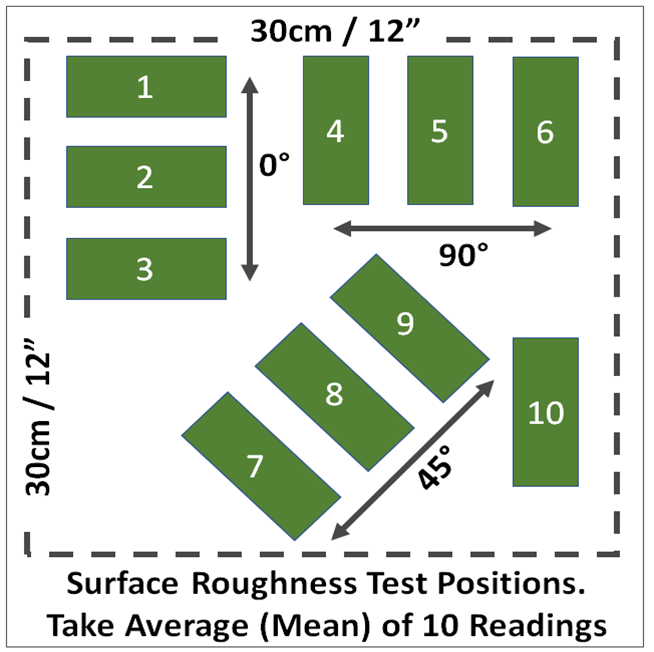

The surface roughness test consists of an average (mean) of 10 readings taken at the same 30cm x 30cm area where the On-Site Pendulum Test was conducted; this is to compare between the surface roughness results and the Pendulum Test Value Readings to give a good overall Slip Resistance. Assuming a Floor Pendulum Test was conducted at the same time though the Surface Roughness Test can be taken independently and is often used to Monitor / Check Floor Wear

Test Positions in Surface Roughness Testing

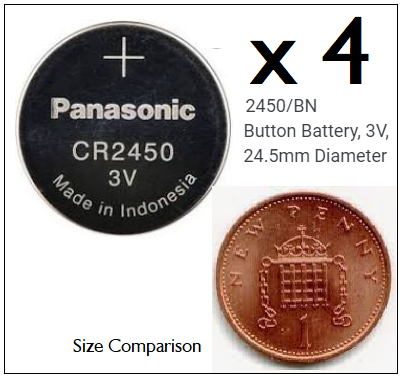

Surtronic Duo Batteries

The Surtronic Duo-2 / 5 (code M112-3115) is powered by replaceable batteries (Four 3V Lithium 2450 batteries, one in the Control Unit and three in the Traverse (Ground) Unit).

The most recent Duo-9 Surtronic Duo is powered by rechargeable batteries possible of taking 2000 readings on a single charge via the USB mini charging port.

Surtronic Duo Batteries

Links to Surtronic Duo Data (pdf's)

Mk 2 Link ('Kenny' Plastic Case)

Mk 9 Link (Rubberised Case)

How much does the Surtronic Duo Cost?

Approx. £2000 plus VAT (2022), quite a large outlay.

Why not Contact FloorSlip Today to save £1000's and get us to test for you.

Do FloorSlip sell the Surtronic Duo?

No. But we can test your floors to save you the large outlay – Contact FloorSlip Now

Where can I buy the Surtronic Duo Floor Surface Roughness Test Equipment?

Spectrum Metrology (Leicester England) are the UK sales distributor and approved technical/applications support and service centre for the Taylor-Hobson range of electro-optical metrology products (including the Surtronic Duo).

Link to Surface Roughness Tester Information

Link to Email for Spectrum Metrology Sales Department

Tel UK (+44) 0116 276 6262

Taylor-Hobson is an English company founded in 1886 and located in Leicester, England and part of the AMETEK Group.

Link to email for Taylor Hobosn Sales Department

Can I buy a second hand Surtronic Duo?

Yes – We see them available for about £300+ on line for the earlier Duo-2, which is a capable piece of equipment PROVIDED IT WORKS. Do not buy one unless the seller can give you video proof of it working and showing the floor giving Rz readings and showing that the self-calibration is accurately working. The equipment is quite sensitive and any knocks and drops can damage it.

Other Surface Roughness Parameters

The other ISO 4287 parameters capable of being measured (not used in floor testing but are used in engineering measurements) are: -

- Rz (Average peak to valley height)

- Rv (Max profile height below mean line within sampling length)

- Rp (Max profile height above mean line within sampling length)

- Rt (Maximum profile peak to valley height)

- Rz1 max (largest peak to valley in any sampling length within an evaluation length)

- Rsk (skewness - measure of profile symmetry about the mean line)

- Rq (root-mean-square (rms) of value of departures of profile from mean line)

- Rku (kurtosis - measure of the sharpness of the surface profile)

ISO Standards for the Surface Roughness Test Equipment

The surface roughness testing equipment follows procedures as determined in ISO 3274-1996, ISO 4287-1997, ISO 4288-1996, ISO 11 562 and other international standards