About the Floor Testing Equipment

How the Floor Testing Equipment Operates

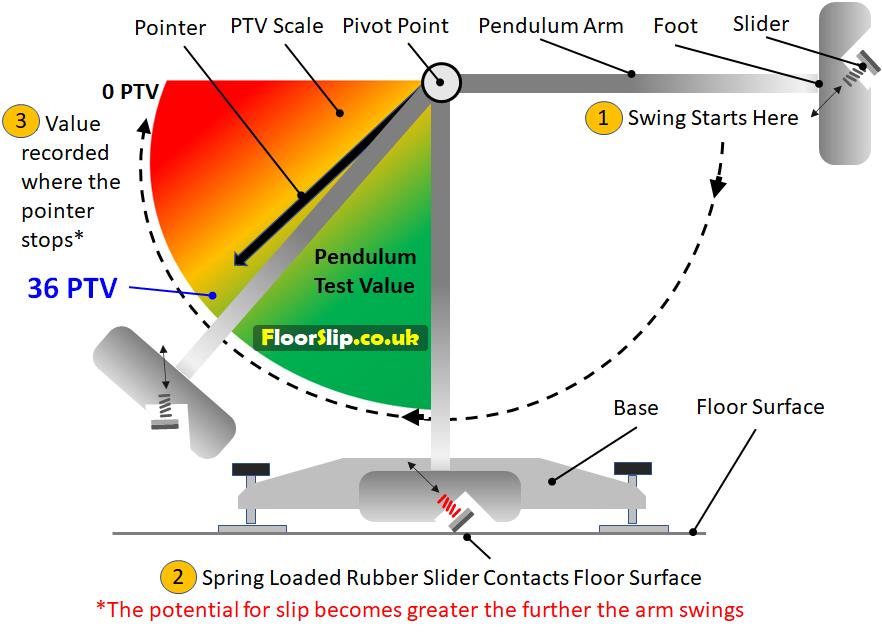

Description of Operation - The Pendulum consists of a heavy base to which a faceplate is affixed on an upright that has the Pendulum Test Value (PTV) Scale marked upon it. Mounted at the Pivot Point of the Scale is the Pendulum Arm. It is this arm which is swung across the floor surface at a predefined distance from the surface and on the end of this Pendulum Arm is a heavy weight (the ‘foot’) to which a spring loaded ‘Rubber Slider’ is fixed on the underside. On contact with the floor, the rubber slider drags across the floor surface, causing the arm to slow down and the quicker that the arm is slowed, the less distance the pointer travels along the scale and the better the friction or 'PTV' result of the floor surface.

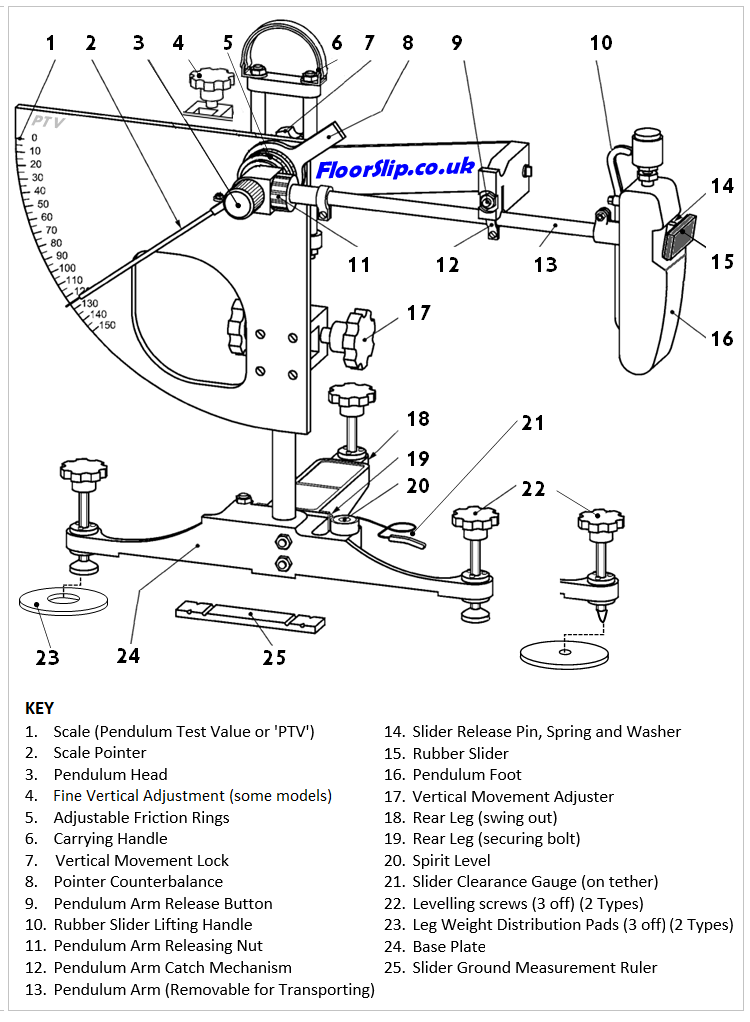

Floor Pendulum Testing Equipment Diagram

The diagram below is generic showing the typical features of the Pendulum Test Equipment. Those used by FloorSlip as well as the New Floor Testing Equipment sold by us are manufactured in the UK to EN-16165 (and previously under BS-7976)

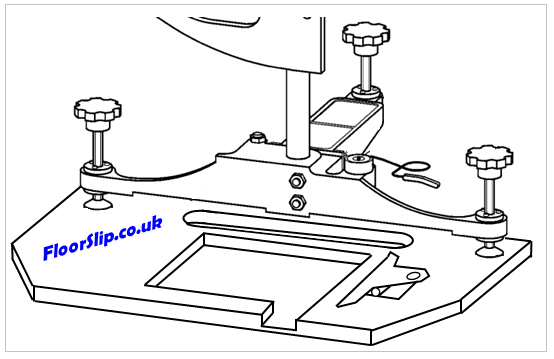

Samples Holder set in place under the Pendulum Feet

Who can use the Pendulum?

The Pendulum is not a complicated machine, but its use by an untrained person can mean results may be incorrectly arrived at or interpreted; it is always recommended to get Training in the Pendulum Test Equipment. The equipment is also sensitive to damage.

Brief History of the Floor Slip Resistance Pendulum Test Equipment

The Floor Pendulum Test Equipment was developed in the 1940’s by American Percy A. Sigler (US Dept of Commerce/ US National Bureau of Standards) who also published books upon the topic of Floor Safety. In the 1950’s or 60’s, the UK Road Transport authorities used the Pendulum to develop a method for testing road skid resistance. This developed to the Pendulum being used for pedestrian floor surfaces and by 2002, a British Standard (BS-7976) had been written to support its use; replaced by Pedestrian Floor Testing Standard EN-16165 (2021). Note - Roads are tested using BS-EN-13036-4. Oddly enough, the Pendulum is often referred to as the ‘British Pendulum’ when it actually originated in America.

How much 'friction' is required to make a floor safe?

The amount of friction measured is termed the ‘Coefficient of Friction’ (CoF) best known as the Pendulum Test Value (PTV) which equals CoF x 100. The UK HSE has deemed a floor should give 36PTV on a horizontal floor surface when the floor is tested WET to give a ‘Low Slip Potential’*. Less than 36 PTV reduces the ability to prevent safe floors quite markedly because the CoF / PTV scale is nonlinear when it comes to probability of slip. A value of 36 PTV giving a Probability of Slip of 1 in 1,000,000 (one million) whereas 34 PTV reduce this by ten times the amount to 1 in 100,000.

Note that Floor Slopes require greater values of PTV by 1.75 PTV per each degree of slope.

The Floor Pendulum Test is augmented by the Surface Roughness Test

*EN-16165 states 95% of slips occur on wet floors